If you have owned a British motorcycle for any time you will be familiar with the term “wet sumping”.

This tech article will focus on Triumph, BSA, and Norton motorcycles. The basic principles can be applied to any dry sump system.

First we should explain the difference between wet sump and dry sump systems:

In this article a Sump is the lowest part of an engine crankcase where oil drains to.

Wet sump means the crank case is used as the oil reservoir. This is common to most modern 4 stroke motorcycles and automobiles today. Royal Enfield was the only British machine that comes to mind that use a wet sump design. In a wet sump engine oil circulates inside the engine and returns by gravity to the lowest part of the engine. The main advantage to this system is simplicity. The disadvantage is the engine has to be larger to house the oil sump.

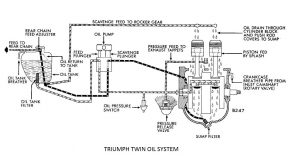

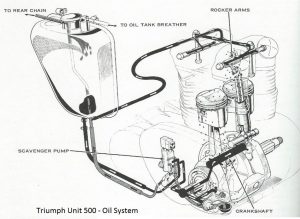

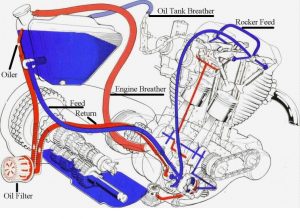

Dry sump means an external oil tank is used as the oil reservoir. Very little oil collects in the crankcase hence a dry sump. Oil is fed mostly by gravity to the engine from the oil tank. A pump circulates oil and gravity returns oil to the sump. The scavenge or return side of the oil pump returns oil to the external tank by means of a metal tube in the sump. On its way back to the tank some pressure is bled off to feed oil to the top end rockers. Advantage to this system is reduced engine size, as the oil is stored externally. Also storing the oil outside the engine means it tends to run cooler. The disadvantage is complexity. In a dry sump system the pump not only needs to supply oil to the engine but to return it to the tank.

The term wet sumping is used to describe when oil fills the crankcase of a dry sump system. The symptoms of this is typically excessive smoking and oil coming out the engine breather tube.

There are two causes for this: Oil is not returning to the tank or oil is seeping through the pump while the engine is sitting unused. Both are oil pump related issues.

The oil pump is the heart of any engine If it is worn out it will not preform its job. For the 3 makes we are looking at there are 2 types of pumps employed:

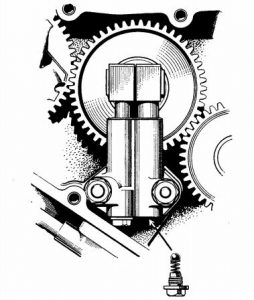

Simple Dual plunger type pump – Triumph

Rotary Gear type pump – Norton and BSA

With the engine running look inside the oil tank. You should see oil returning from the froth tower near the cap. It may not be a steady stream but intermittent every few seconds. If no oil is returning shut the engine off and investigate. Removing the crankcase drain will be the dead give away. No more than a few ounces should be found in the sump.

TRIUMPH PLUNGER PUMP:

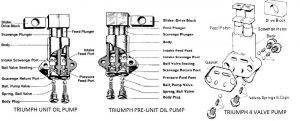

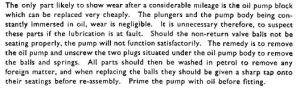

On a Triumph the issue is usually debris in the oil pump. Even a small bit of debris can prevent the check balls from seating. Triumph 650/500 unit and Pre-Unit both use 2 check balls. 750 twins use the same 2 ball design till 1979 when the 4 ball pump was introduced. Triumph Cub also uses 4 check balls. You might notice the scavenge and return plungers were reversed when the Unit engine was introduced. The scavenge side plunger is usually larger. This side of the pump should be examined for wear if you have no oil returning to the tank. On an engine with chronic wet sumping issues checking the feed check ball(s) and scavenge side plunger is a great place to start your investigation. The 4 valve T140 pump can be used on 650 Unit motors with slight modification to the inside of the timing cover. Having two extra check balls helps control sumping.

Below is the factory manual instructions for seating the check balls in a plunger style pump:

Pre-Unit Triumph and 500 Units Models:

If a new pump fails to solve the problem than the pickup tube could not be sealing in the case. This will require splitting the crankcases to renew the o-ring that seals the pickup to the case oil passage. This is not a common occurrence, but worth mentioning. This should only be explored if all other avenues have been exhausted.

Norton/BSA Rotary Type:

BSA twins employed a single ball and spring, non-return valve, on the feed side of the pump. Norton only introduced this on the MK3 models. In both machines worn pump bodies tend to wet sump over time. Both the BSA and Norton pumps are being reproduced in higher than factory qualities. Closer tolerances in the new production pumps eliminate wet sump issues. Still a bike the sits for extended periods of time will collect some oil in the crankcase.

In all cases where wet sumping is an ongoing issue we recommend our inline Anti-sump valve. It gets installed in the feed line before the engine. The valves are designed so that very little negative pressure (3-5 psi) is required to open. The anti-sump valve will not help a worn out pump return oil to the tank. If the pump can’t scavenge oil it will still need replacement.

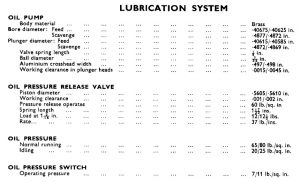

Some oil pressure figures:

There was a dealer tool for checking pressure and vacuum. It was manufactured in the USA for Triumph by Dunleer. A replica of this tool is available upon special request.

Triumph Twin

Triumph Scavenge Vacuum:

Fast Idle Vacuum gauge should read 18-26 inches of mercury. Reading is done by connection a gauge to the scavenge tube at the case sump plug.