Thread Pitch and Screw Types

When it comes to hardware there are a number of different fasteners on a British Motorcycle. Being able to determine the thread pitch is critical to ordering the proper part. It also assists us in supplying the proper fastener for the application. That is if you plan to order without part number.

As William Shakespeare’s Hamlet lamented: “To 2BA, or not 2BA, that is the question! Whether ’tis not metric or 10-32. Oh suffer the slings and arrows of repairing damaged threads. Installing helicoils and welding holes.” Or something like that.

Many threads have similar dimensions which can confuse the less experienced mechanic. Especially when dealing with any British machine. Two note worthy examples would be: the 2BA screw thread and the 1/4×26 Cycle Thread.

(2BA)Measuring with a pitch gauge the 31.4 thread per inch pitch (tpi) may be misidentified as 32tpi or as a US 10-32 pattern thread screw thread. While they might seem compatible the problem is the major diameter is different. The US 10-32 has a major diameter of .190 vs 2BA at .185 – this is where a venier or digital caliper is handy. To complicate things even further we have the metric 5mm x 0.8 screw. This fastener has a tpi of 31.75 with a major diameter of .196

The 1/4x26CEI has previously been confused with 6mm x 1.0 metric as the pitches are close (.977 vs 1.0). Again the major diameter is the give away. 1/4 (.250) vs 6mm (.236) inches.

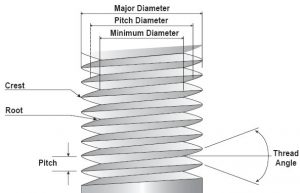

Below is how to identify screws based on thread count and diameter.

The simplest way to measure thread pitch is with a thread gauge. These are available from us and any company that sells hardware.

The bolt diameter should be measured and matched to the nearest size with matching thread pitch or threads per inch (TPI).

In general, the major diameter of a bolt will be slightly less than the exact diameter listed in the thread identification and drill chart .

Fraction to Decimal Conversion Chart includes Metric equivalent

Further reading:

Origin of modern thread systems – Thread standardization under the Whitworth System

Pitch Conversions:

Sometimes you don’t have the thread gauge you need on hand. For example you have a metric thread pitch gauge and you need to know the thread per inch or TPI.

Example:

The -20 in “1/4-20” signifies “20 threads per inch” =Or .05 pitch in inches ( 1 divided by 20 ) or if you are measuring with a metric pitch gauge it should be 1.27

Use the link below to identify threads. Care must be taken to not confuse metric and imperial thread pitches. Attention to both the major thread diameter and pitch are critical to identifying the bolt.

Click here for a comprehensive chart

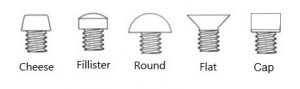

This section will mostly pertain the engine case screws. There are plenty of specialty fasteners out there you won’t encounter on a British machine. We will only mention what you will encounter.

Cheese Head – Traditional case screw head style supplied in slotted drive

Fillister Head – Similar to cheese head but with a rounded top available in slot and Pozidriv

Round Head – Points cover screw head style – slotted and Pozidriv

Flat Head – Typically countersunk and found inside the engine – slotted and Pozidriv

Cap or Allen Screw known to some as a socket head – Not stock to British machines but available as an upgrade for case screws

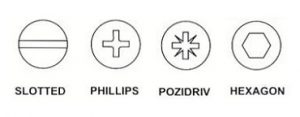

Pozidriv- The Pozidriv is an improvement on the Phillips drive by increasing its torque capacity without increasing the likelihood of cam-out. It also has greater surface area contact with the drive recess. This makes it less likely to strip when installed correctly. Be aware there are some Chinese made “posidriv” screws that simply have the lines on the head but lack the additional surface area in the tool well/recess. So basically they are passing off a standard Phillips as something it is not. Many of the cross head screws we supply are only available in the Phillips style.

JIS – There is third cross head screw which is worth mentioning. While it would not normally be encountered on a British machine it might appear on a Japanese made accessory, such as a switch cluster. The JIS or Japan Industrial Standard screw head closely resembles the standard Phillips. The difference is the recesses are narrow in the center as well as near the outer edge of the screw head. JIS screws can be ID’ed by the dimple stamped between two arms of the cross.

For specifics on thread profiles and history view our article Whitworth and Other British Threads

Details on methods for threading including: cutting, rolling, and casting Click Here.