Click here to download the PDF

Needle, needle jets, and the Amal Concentric

The Amal concentric carburetor was introduced as a cost saving measure dictated by

the British companies to IMI Components, owners of Amal carburetors LTD. The first

of these came fitted to the BSA Spitfire MK 3 in 1967 and most of the factories followed

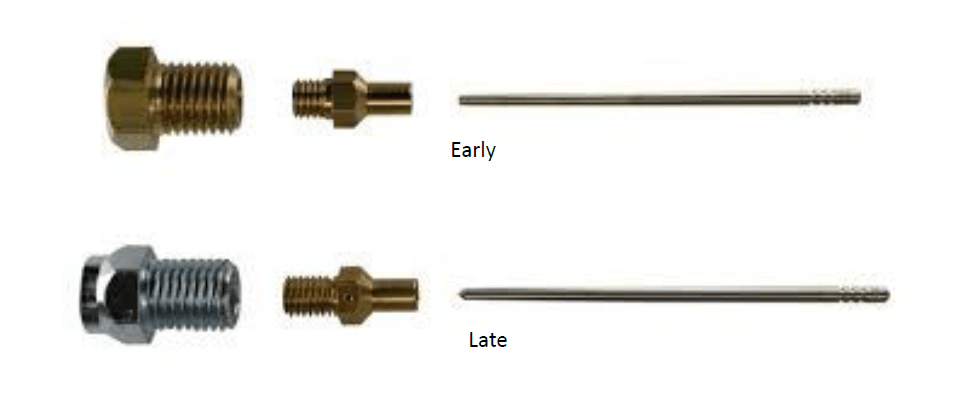

shortly after. The first Concentric had a removable pilot jet threaded into the

base of the body. They also used the shorter 622/063 needle and early non-cross

drilled needle jet 622/079-106 along with the short needle jet carrier 622/080. These

components were changed for 1969 to the updated parts needle 622/124, needle jet

622/122-106 and the needle jet carrier 622/128. Amal sold these components as a set

to update older carburetors as Amal number 622/235 conversion set.

Wear and corrosion take a big toll on these components and it is good practice to replace

the needle and needle jet as a set when they have been in service for more that

10,000 miles or even less under dirty conditions. It is amazing how much these components

can improve running and mid range throttle response. The early and late

components are never to be mixed in service.

Needle Jet Notes:

Needle jets are the only Amal jet where the number refers to an actual inch dimension.

The rest of the jet numbers refer to rate of flow in cc’s (cubic centimeters) per minute.

Gasoline carburetors, both two and four stroke, are commonly fitted with needle jets ranging from .105- .107.

The .106″ needle is by far the most common one used. Needle jets measuring .1065″ have been made.

Alcohol carburetors are commonly fitted with needle jets .120″ or larger.

Changing one size either way from the proper needle jet has a strong influence on just off idle to mid range running.

A slightly worn, or oversize, needle jet will cause the motorcycle to run very rich at throttle openings up to approximately 1/3rd throttle.

The crossed drilled hole in the 4 stroke needle jets can be made larger to lean out the mixture at low

throttle openings. Enlarging this .035″ hole has the greatest effect while the straight portion of the needle

is in the needle jets metering orifice. As little as .001″ increase in the size has an strong effect upon the

amount of fuel the needle jet will deliver.

The largest advisable size of the needle jet cross drill hole is .039″.

As

the hole approaches .050″ the carburetor stops working properly. To save embarrassment later, be sure tomark the needle jet as oversize.

Enlarging the size of the crossed drilled hole can help clear up a bike that has megaphonitis.

We found that

0.039″ cured megaphonitis on a Triumph 500 twin kitted with Triumph megaphones.

You can use a reamer to enlarge a needle jet. If a .106″ is too small, and a .107″ large you can ream the jet to .1065″.

If you work on these carburetors as a part of your daily routine a set of Plus and minus .105″, .106″ and

.107″ plug gages are handy.

Other Needles you may encounter:

Click here to read more about Concentric Jetting in this Vintage Bike article by John Healy