Click Here to download JRC Carb Tuning Guide

Click Here to Order JRC Carb Spares

INSTALLATION GUIDE FOR

THE JRC 24-30MM FLATSLIDE

CARBURETOR

Introduction

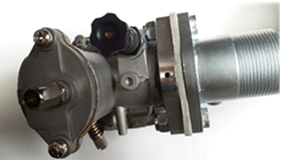

Congratulations on your purchase of the JRC flat slide carburetor. This carburetor has been developed to give better starting, engine performance, and throttle control for your classic motorcycle. The procedure to install it, depending on the level of experience of the installer, takes approximately 60 minutes to perform.

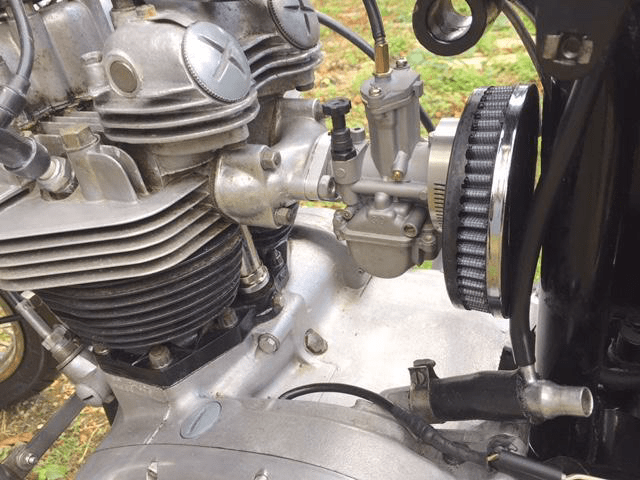

Fig.1

Note: A cable operated choke is available for single, twin and 3 cylinder applications.

Tools Required:

Whitworth wrench set pre 1968 British Machines (tightening flange nuts, 1/4w, 5/16bs)

SAE wrench set post 1967 British Machines (tightening flange nuts, 7/16 and 1/2 sizes)

Metric wrench set (for removing: float chamber plug 17mm, main jet carrier 10mm, main jet 6mm)

Phillips or cross head screw driver (removing: the carburetor top and float chamber)

– latest carbs have 3mm allen screws (key provide with carb)

Flat head screw driver thin (removing the pilot jet)

Installation Procedure

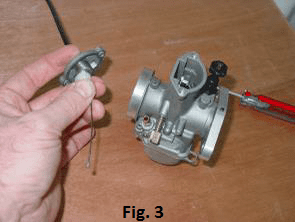

The first step is to disconnect the battery to ensure no sparks occur around gasoline vapors. Then remove

the old carburetors and gasket(s) and detaching the throttle cables. Be sure to take extra care with regard to fuel

during this step. Gasoline is extremely flammable and fumes may be ignited by appliance pilot lights from a

surprising distance. Be careful to work in a well ventilated area. When in doubt work outdoors.

This will leave the manifold bare as shown. (Royal Enfield Bullet shown)

Fig.3

Step two involves attaching the throttle cable to the slide assembly. To do this unscrew the two screws at the

top of the throttle slide housing assembly taking care to keep a finger on the top as once the screws are

undone the spring inside will push upwards.

Removing the top cover, the spring, white collar, will leave the chromed slide and needle inside the housing.

Having removed the top cover, push the nipple

end of the throttle cable through the top cover

and down the center of the spring and through

the white retaining collar. Note that the white

retaining collar must be installed the same

direction it comes out. Compress the spring

and hold it all together so as much of the cable

is showing as possible.

Note: Return springs of different spring rates

are available from your dealer.

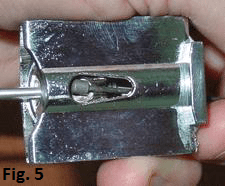

Fig. 4 Now insert the end of the cable so that

Fig. 4 Now insert the end of the cable so that

the nipple sits in its place in the throttle slide.

Fig.5

JRC Superior carburetors are pre-jetted if the application is specified upon ordering. If no application was given the carbs are supplied with the factory jetting specs. Jetting is done for the stock motorcycle not taking into account any modifications that your bike may have. If you tell us, for example: that your bike has open pipes we can adjust the specs accordingly.

Insert slide into the throttle housing ensuring it is the correct way round. NOTE – there

is only one way it can be inserted, no force should be applied for this.

Fig 6.

Fig 6.

Re-position the top cover and screw back into

place taking care not to over tighten the screws, Be

sure that there is enough free play in the cable that

the throttle slide sits full closed.

NOTE –The weight of the carburetor should not

hang from the cable alone. Support the carburetor

with a length of wire.

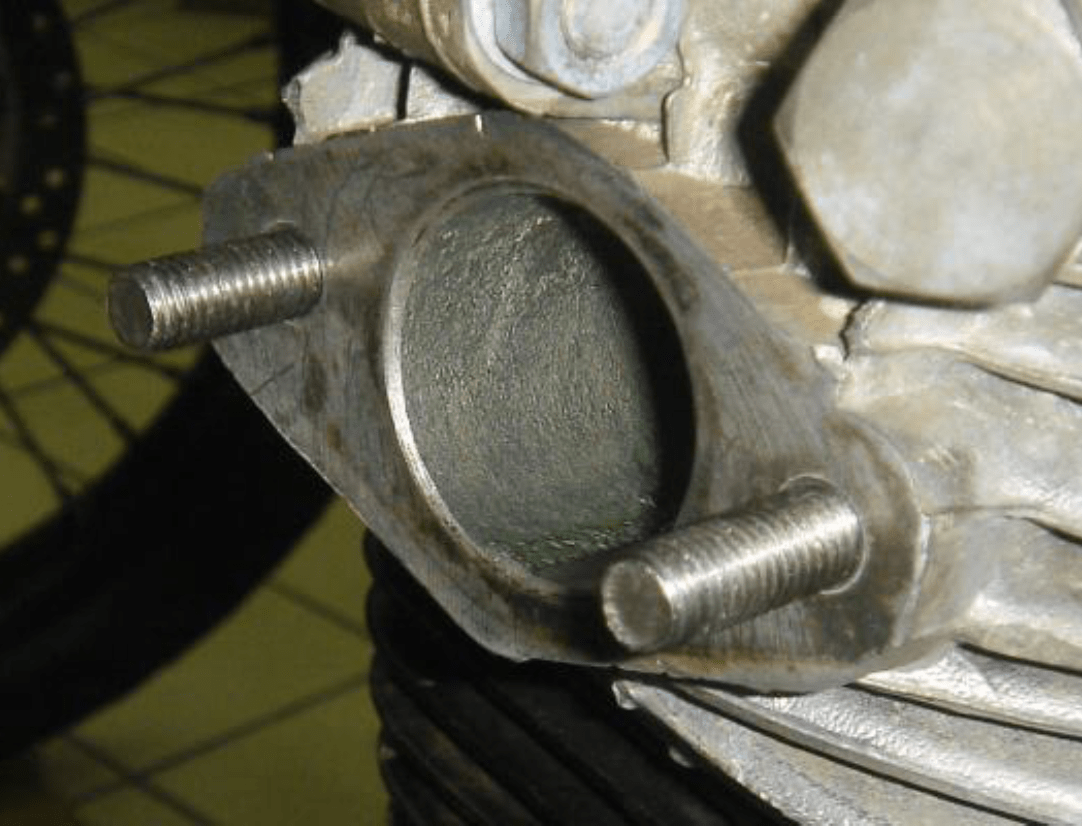

The next step is to ensure the ‘O’ ring is in its seat on the face of the flange and the gasket is on the

threaded studs against the head. Mount the carburetor onto the studs fully and put on the washers and nuts and

tighten them up with the open ended spanner. Do not over tighten the nuts.

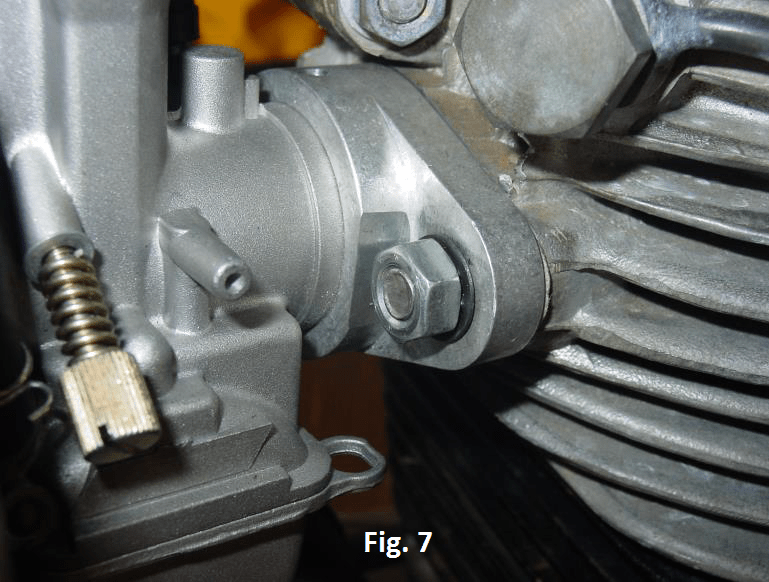

Fig.7

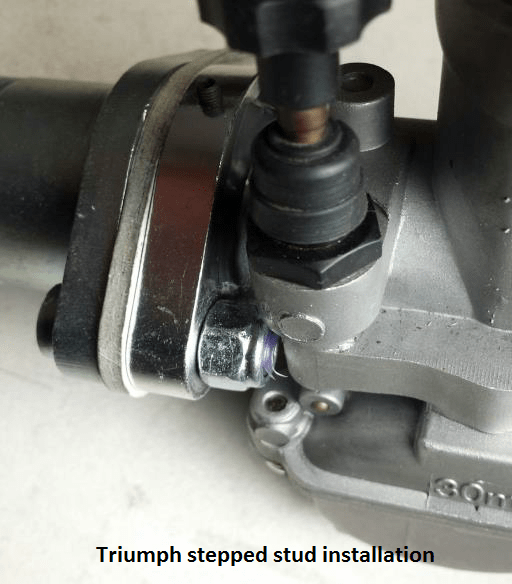

Note: On 1969 and later Triumph models delete the cupped steel and rubber washers and replace with

flat and lock type nuts. Make sure to use the insulator block 70-2968 on all applications. Your

machine had these fitted with the original carburetors and it is acceptable to re-use them.

(Fig. 7 Royal Enfield specific unit)

Top picture showing heat insulator and lock nuts on Triumph manifold.

With limited space the use of a thin nut on the choke/enrichener side is advised.

Also a heat insulator between the carb and manifold/head is recommended. Otherwise the left hand mounting stud may be too long and need to be shortened.

Our 2 inch flanged carbs are supplied with a thin nut in both early and late 5/16 threads.

Thinner nuts are available:

5/16×26 CEI Pre-68 machines – 57-0224

5/16×24 UNF Post 68 machines – 14-0402

Heat insulator:

available in 26-32mm bore sizes

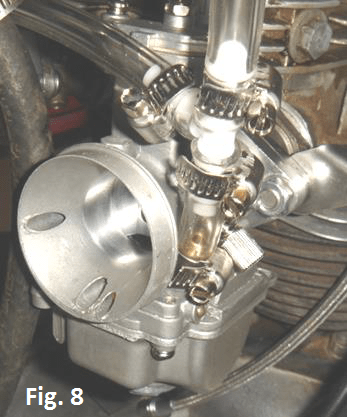

Fig.8

Final step is to fabricate fuel lines. Always use clamps on fuel hose and always use

ethanol resistant hose. A 12 inch piece of fuel line, and hose clamp, is included with each carburetor we sell. We can supply addition hose and fittings if needed.

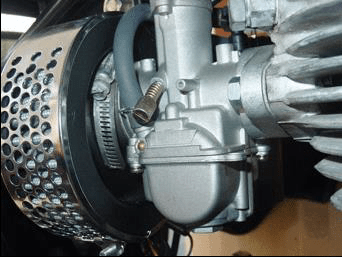

Now fit the air filter. The stock pancake Volkes type filter will fit as long as it has the removable insert and is for a 900 or 389 series Amal carburetor. The 26mm Amal has smaller threads so a larger filter must be ordered. (also available from JRC Engineering, please see website or catalog for details). Offset inlet for single carb and center inlet for twin carb models is the typical set up for air cleaners after 1967.

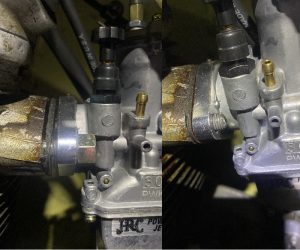

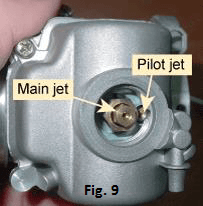

Fig.9 Jets

The carburetor comes with extra jets, a pilot and four main jets. The main jet and needle jet can be

changed easily whilst the carburetor is mounted in place on the bike. Changing the pilot (slow jet) will require unmounting from the engine.

To replace the main jet, the

bottom large nut at the base of

the float bowl can be removed,

Fig.9 (remember to turn off your

fuel tap from the tank). Some

fuel will spill out so have a large

rag or bowl to catch it. A couple

of small spanners will be

needed to remove the jet.

Tools Needed:

17mm wrench (drain plug), 10mm wrench (main jet carrier), 6mm wrench (main jet)

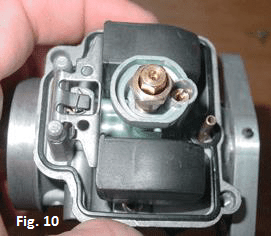

For changing of the pilot jet, the float

bowl needs to be removed to gain access

to it and this can be done by removal of

the two screws. Latest batches use 3mm allen key (included with carb).

NOTE – the bowl needs

to be gently maneuvered around to

release it as there are the floats and

internal structure inside. This must be

done very gently for both removal and reinstallation.

Fig. 10 shows what is there

once the bowl is removed (in the photo

the carburetor is removed from the bike

and sitting on a bench).

Removal of the slow speed jet requires a flat blade screw driver. It is important to use one that is large enough to fill the slot in the jet. Otherwise the jet can be damaged resulting in added work of removing the broken jet. A bit of WD40 around the jet can loosen stubborn threads.

Now the question is:

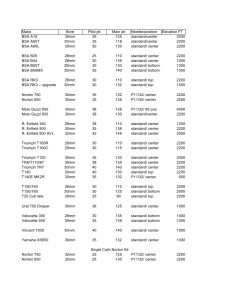

How do I determine what size jets I need? Is there a crossover chart between Amal and JRC (Keihin PWK) jets?

Sadly there is not a crossover. And here is why:

UPDATE: I have compiled some jet sizes and flow rates to give some sort of understanding to how Keihin jets relate to Amal jets. All based on the assumption that a metric equivalent bore will pass a similar amount of fuel. The bold figures in the chart are based off actual plug gauge sizes for checking Amal jets. We converted the Amal bore to metric which gives a size metric size and therefore a jet number. Read further for a details.

Click Here to View Jet Comparison Chart

Amal jet numbers represent the flow rate expressed in (cc’s) cubic centimeters of fuel per minute. IE: a 150 jet will pass 150cc/min. Pilot jet #25 – 25cc/min. The Amal needle jet is the only jet that the number reflects the actual orifice size. IE: 106 is .106 inches. Read more about Amal carburetors in this article – Click Here

For Keihin Carbs the jet sizes refer to the metering orifice diameter, expressed in millimeters. IE: A 100 main jet is 1.00mm in diameter. A 120 main 1.2mm. Slow jet # 38 is 0.38 mm in diameter. Based on our chart, several lines above, you will see that Keihin pilot jets and Amal jets can share the same size orifice. IE #20 Amal pilot jet measures .015 inches or .38mm. The #38 (.38mm) flows 20cc of fuel per minute. So it would be safe to make the assumption that both must flow similar volume of fuel over the same amount of time. New Premier Concentrics run best with a #19 removable jet (these are only made in odd number sizes) which is really close to the #38 we supply in the JRC Keihin for the same application.

So at least for the slow speed jets there is a correlation between Amal and Keihin jets. The problem with main jets is that the Amal and Keihin bodies flow different rates of air so it is not so simple. For example for Triumph 650 Bonneville the Amal 200 jet is typically fitted. This is comparable to a 122 Keihin in terms of fuel flow. With more air more fuel is needed to get the correct air/fuel mixture. In the Keihin a 130 main is typical for Triumph Bonneville. You will see in the chart that this Keihin 130 jet bore is comparable to a 230 Amal jet. This gives a basic idea of how the two carburetors relate in fuel requirements.

Below you will find a chart of tried and tested jet specs for various machines. We continue to add and revise this list so please forgive us if there are any errors. If you don’t see your machine listed here contact us for additional information. We can make an educated guess of where one should begin tuning. If you have specs, not listed here, that you wish to share we would really appreciate it.

DISCLAIMER

The steps in this guide are just that, a guideline only. Anyone wishing to install the carburetor

does so at their own risk and JRC Engineering cannot accept any liability for any loss,

damage or claims arising as a result of any work or action carried out based on the

information given in this guide.

Note:

1. Always turn fuel taps to “Off” position when the engine is not being run, even for a short

time.

2. All rubber components supplied with JRC Carburetors are suitable for use with 10%

ethanol fuels however with the advent of 15% fuels JRC does not recommend use of any

greater than 10% ethanol blends.

3. It is recommended also that all rubber O rings on jet blocks and float bowls be replaced

whenever they are disturbed. We have priced these at very low cost to encourage

replacement.

4. Ethanol and the moisture it attracts is extremely corrosive so we further highly recommend

that if your motorcycle is to be left standing for more than two weeks that you drain the float

chamber by removing the drain on the bottom. Ensuring the fuel taps are in the off position do

this in a well vented area and have a catch basin under the float chamber to capture the small

amount of fuel that will drain out.

It is suggested if you do not feel confident enough to perform the installation

procedure on your own that you engage the services of a professional

motorcycle technician to do so on your behalf

Breather hose locations

While the carburetor body has a few stubs for overflow tubes only two actually are used in our application.

They are indicated below by arrows. The stub opposite the cold start plunger is the only stub on the body used.

Breather number two is on the side of the float chamber. Both tubes should be directed toward the ground.

Their purpose is to direct fuel away from the hot engine in the event of a fuel spill.

If more than a small amount of fuel comes out the float may be hanging up or debris is holding the valve open.

Additional information on your JRC carburetor.

Accessories and kits available;

1. Cable operated choke assembly for single , twin , and 3 cylinder applications

2. Fuel line and fuel fittings to make custom fuel lines

3. Air filters , custom and original type

4. Throttle cables for single , twin or 3 cylinder applications

5. Carburetor kits for Norton Commando single 30 or 32mm

6. Carburetor kit for TR6/7 to fit standard air filter box, 30mm

7. Carburetor kit for T140E 1979-82, replaces Mk2 Amal or Bing

8. Carburetor kit for new Royal Enfield 500, 30 or 32mm

9. Carburetor kit for Ural twins

10. Trident and Rocket 3 gantry conversions to keep stock air box and gantry

Stock factory needle is marked “97A” and closely matches the specs for PWK JJC. Selecting a needle with the third letter higher in the alphabet will result in a leaner diameter. IE JJD 2.395mm diameter is leaner than the JJC with its 2.385mm diameter. Click the “leaner throttle needles” link above for a chart with needle specifications. There are a lot of options on needles but we found sticking to the JJ series gave the best results.

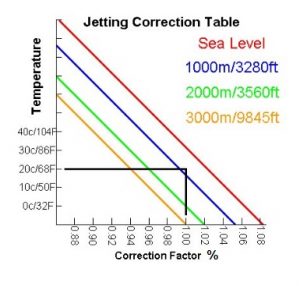

Altitude Jetting – Click Here for more information

For higher elevation 4000 ft +jetting deduct correction factor from the jet size. Round up to the nearest size.

Check out our carb fitted to various applications. Click the links below:

Triumph Bonneville 650 – pair 30mm

Triumph Daytona 500cc – pair 26mm

Triumph Bobber 500cc – pair 26mm

Triumph and BSA 3 Cylinder Machines – three 26mm

Triumph 3 Cylinder Machine – three 26mm No Gantry

Triumph and BSA Unit Singles 250-500cc – 26mm

BSA A7 500cc – 26mm or A10 30mm

Norton Commando 750 and 850 – pair 30mm

Norton Commando 750 or 850 Single carb -32mm

Royal Enfield 350 Bullet – 26mm or 500 Bullet 30mm

Royal Enfield 500 Bullet – AVL motor – 32mm

Royal Enfield 750cc twin – pair 30mm

Moto Guzzi V50 500 V twin – pair 26mm

Montgomery Wards Lawn Tractor -26mm

CUSTOM FITMENT REQUESTS ARE WELCOMED

THE FOLLOWING MOUNTING OPTIONS ARE AVAILABLE UPON REQUEST:Keep in mind when selecting a bore size that you want a smooth transition in the inlet track.

Too large a bore and there will be a step or raised portion that will obstruct air flow.

This will need to be corrected for by slightly beveling the inside of the edge of the inlet manifold.

The largest carburetor might not be the best fit for an application.

Too large and you loose bottom end torque. Too small and the top end performance suffers.

BORE SIZES JRC-30PJ, 28, 26, 24, 21mm:

(NO LETTER SUFFIX) STANDARD 2IN FLANGE

(B) 35mm spigot

(E) 38mm spigot – MK2 carb replacement/ New Ural 750

(A) 58mm horizontal flange – New Enfield

(C) 53mm vertical flange – Ural Dneper/ BMW

BORE SIZES: 32, 34mm

(NO LETTER SUFFIX) 38mm spigot – Norton 2-1 manifold kit

(A) 58mm horizontal flange – New Enfield AVL motorFurther internal details:

Should the need arise to disassemble the carburetor for cleaning the following pictures may prove to be helpful. Looking into the inlet of the carburetor the passage on the left is the cold start or enrichment circuit. There are not many restrictions in these passages so very little effort will be required for cleaning. There is a restricted spot in the float chamber in the way of a pressed in bushing. This should be probed with a small diameter (0.5mm or .020in) wire to clear.

Removal of the jet tower is the best way to get the slow speed passages clear. Push out the float pivot pin and lift the float and needle away. There are two screws that retain the jet block into the body of the carb. These can be one of three different types of fastener: #2 Philips, 4mm Allen, or T20T (tamper resistant Torx). Note removing the jet tower will require replacing the molded o-ring that seals it to the body. It is impossible to reuse this seal as it is likely to be misshapen due to fuel exposure and mechanical compression. (The replacement part number is P21A/B).

Yellow Arrows indicate the slow speed passages. Red Arrow indicates the passage which feeds the main jet for higher speed and off idle running. There are two drillings in the carb toward the rear of the slide. Both of these must be clear for the idle circuit to function. Also the cross drillings in the pilot jet must not be blocked.

The jet “tower” has an “o-ring like” molded rubber gasket. This should be renewed when servicing this part of the carburetor. Unless you can ensure that there is no damage to the o-ring. Failure to seal will result in an air leak and idle issues. A small amount of super glue (cyanoacrylate) needs to be used to hold the gasket in the recess during assembly. Just don’t glue your fingers to together. Acetone (nail polish remover) dissolves super glue if you make a mistake.